Then, there's a layer of prepreg on each side plus copper foil that goes through etching for 3 and 6, more prepreg and another layer of metal that is also etched on what will eventually be layers 2 and 7. It would begin with one thick slab of copper-clad core material that goes through the etch process to get a pattern for the innermost layers 4 and 5. That would be a six-layer board to start. Let's say, for instance, that we're doing this HTC phone. So, getting back to the other definition of core, in the world of HDI, (high density interconnect) we typically start out as though we were going to build a normal PTH (plated through-hole) board and then build up from there. The things you hear twice are probably true across the board, rather than a site-specific requirement. Get to know the salesperson at your favorite fabrication shop. I've praised Texas Instruments for their accessible and informative data sheets so here's a shout-out to their counterpart on the board construction side. Isola is a major manufacturer of PCB materials.

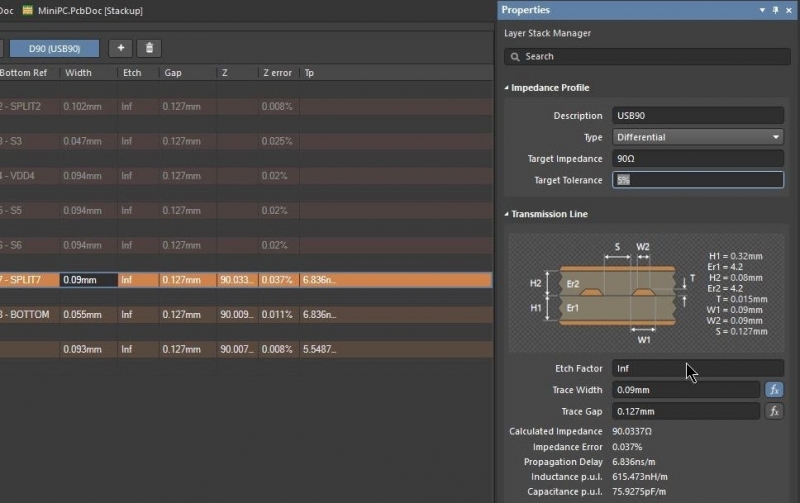

It's a testament to the variability, much like plywood. Some of the materials have two values, one before the press and one after. The recipe is going to vary depending on use and also on where in the world the board is constructed.Īs an aside within an aside, flex circuits are a whole different animal, especially when it comes to stack-up definition. Cores are more consistent so it's common to use them wherever you require special impedance rules. The fabricator can keep piling up prepreg with copper foil in between or can use more core materials. That's just the nature of organically dissolving copper. No two are the same, even within the same panel. You pretty much have to start with the brick but you also need the mortar.Įver wonder why the PCB fabricator cannot hold a tight thickness tolerance? It's because the prepreg forms around the circuit pattern on the core material as it cures. Our mortar starts out kind of gooey and only gets its stiffness under the heat and intense pressure of the press. Our bricks come with metal on the outside. To a bricklayer, the core is the bricks and the prepreg is the mortar. The traditional core is the heart of the stack-up. On Cores and PrepregsĪllow me to define "core" because it is a term that is also used to distinguish materials. You should know this shorthand if you're going to design HDI boards. The general case is to call it 1+N+1 where the N represents the number of layers in the core. In shorthand it's an eight-layer 1+6+1 board.

Blueprint pcb stack up full#

No full stack of micro-vias for these guys, we started with a six-layer core and one additional lamination cycle after that. My particular niche was the so-called feature phones. Their aim was a little different from the high profile smartphones. It's sweet irony that the outfit that Qualcomm had me servicing was HTC given the latest merger news.

All SOCs (system on chip) tend to work this way. Having fewer tricks to do also reduces the number of different power domains that need to be fed into the chip. The more features you want, the more GPIOs you're going to need.Ī virtual reality headset can get away with a lot of no-connect pins while an ordinary "feature phone" needs more signals fanned out of the device, and a smartphone requires the full allotment. The device has hundreds of GPIO (general purpose input/output) pins. The plan can be tailored to any use you may require. If you ask nicely, and you have a billion (with a capital "B") to spend rolling out your own phone system, they will come up with a plan just for you. They shared a portion of that fee with me and a small army of engineers to come up with the plans. I use "license" because they're not going to build or sell anything physical but you can have access to the plans for a fee. The blue Q provides what they call a Qualcomm Reference Design (QRD) for each chip they license. Qualcomm's Snapdragons are a case in point.

If the "mother of all devices" demands ten stacked micro-vias, then that's the cost of entry. If a four-layer, through-hole board will cut it, that's the way to go. We shouldn't play favorites, the best stack for the job is the one we should be using.

0 kommentar(er)

0 kommentar(er)